In the majority of cases, we do not anticipate needing significant groundworks, or the removal of old surfacing prior to laying. Cement mixers are not suitable for this work, nor do we recommend the use of rollers.

Important note: these are not instructions and if followed does not guarantee a successful surface. Variables on the day may include the weather conditions (temperature, air moisture etc.), time in & the motion of the mixer, time taken from mix to spreading, compression achieved etc.

The Process:

Equipment needed – mixer, mulch bags, binder kegs, trowels, measuring jug, battens

In very simplistic terms, the installation is carried out as follows:

Prepare ground if needed; prepare edging; lay geotextile (in most cases); Add bag(s) of rubber mulch in mixer, measure binder and add in mixer; mix until ‘evenly wet’; transfer to barrow; using batons to maintain correct depth, spread the mix with a hand trowel with downwards pressure, regularly wipe clean all tools with water to keep them clean; apply trowel again to leave a smooth top surface.

For the binder, the effective working air temperature is usually from 5-25 degrees. Variations in weather conditions may affect the curing (drying) time and, certainly, care must be taken that it does not rain during installation or curing time. Note that our Ecobond™ binder has a much faster reaction time than others so the technique will need to be adjusted accordingly, but this gives us the opportunity to work in a wider range of weather patterns, often working in winter when others may not.

Once delivered, binders must be stored at between 5-25 degrees and it is not possible to store opened containers (once the chemical reaction has started). Note that our binders are solvent free, however care should be taken not to allow any binder onto bare skin etc. See container label for emergency contact details. Full safety data sheets are available on request.

Our installation

| Included in the Gummibond™ service | Gummibond™ | Others? |

| A 5 year warranty on the integrity of the installed surface | ||

| Multiple individual areas on the same site can be agreed | ||

| Can agree to blending two colour mixes on site | ||

| Graphics and patterns can be agreed | ||

| Different coloured areas on the same site can be agreed | ||

| Carry a material float to deal with minor ground undulations and reasonable inclines, etc. | ||

| Clear the site of all generated site waste including hiring of skips as & when required | ||

| Clear the site of all unused materials | ||

| Provide orange security fencing when needed | ||

| Take responsibility for overnight storage of materials | ||

| Absorb any disruption caused by adverse weather conditions | ||

| Follow dimensional drawings and aesthetic plans accurately | ||

| Will have on our files minimum public liability insurance of £5m | ||

| Will respond to snagging or warranty issues within 3 days of initial report | ||

| Will take responsibility for all on site safety / security / disruption to site until surface is cured | ||

| Expertise to work with hills and mounds | ||

| Will, where the mulch surface finishes to the ground, be responsible for ensuring there is no trip hazard on or off the laid surface | ||

| Will use geotextile when installing over all loose surfaces such as grass, etc. | ||

| All edges to be secured by a variety of methods depending on surface to be covered and any existing boundaries | ||

| Full depth mulch system used without the use of cheaper and weaker sub bases | ||

| Experience of installing indoors | ||

| Experience of installing in a range of countries and climates | ||

| Will ensure edges comply with disability access ratios |

Indoor use?

Yes we have used it very successfully indoors, however you should contact us for advice as there are specific considerations you should be aware of.

Drains?

We have various methods of managing drains within the area to be covered: we can cover them over and accept that the surface will need to be cut into if access is required later; work around them and leave them exposed, or cover them with a different coloured rubber mulch so they are easily identifiable. The only time we will raise an extra charge is to cover the cost of a raised frame if needed.

Graphics, patterns and colour schemes?

Yes; we can change colours to make different colour pads on the same site, we can mix 2 colours together to make a variety of ‘fleck effects’. We can follow designs or sketched out ideas, or you can simply allow us to free handsome patterns of our own. We will normally be able to do this without any extra charges being made. The only restriction is that due to the size of the shred, it is not possible to make small, very detailed graphics such as numbers and letters.

Obstructions?

Our experience allows us to deal with deliberate or naturally occurring obstructions such as fences or trees etc. by working around, through or between obstructions, often saving the time & the expense of removing or damaging them.

DIY install?

Professionals make it look easy; we can compare it to the plasterer in your home; I am sure they could tell you how to mix it and trowel it on, but most of us could not get it to be that smooth and onto ceilings! If you use our rubber mulch systems you can easily end up with a surface stuck together on the ground, it may even be useable for a while, but if you want to get the maximum durability and safety performance out of it then it is probably best left to the professionals. For all self-install projects then our role is a component material supplier only; our section on warranty makes our responsibilities clear.

Material coverage rates:

As you must expect, the size and shape of the rubber mulch shreds will have an effect on the amount of material you need so in brands where these are smaller, or not controlled, or have the addition of granulate particles, then it will not be possible to specify exactly. This, along with the multitude of binder qualities on the market also makes it impossible for us to comment as to the amount of binder you may need in the mix when using uncontrolled materials from generic waste streams from other suppliers.

As the rubber mulch material in our Ecobond™ brand is carefully managed and is all shred, without granulate, then we can be very confident that in test conditions you will require 16 kilos per square metre at our normal depth. However we cannot expect to have a perfect real-life installation so you should allow extra material to smooth out any undulations in the existing surface, extra for digging in the edges, and if going over an existing safety surface pad or over the new Pro Base Pad™ system then you have to allow extra square metres for ramping down and into the ground to ensure the new surface completely envelopes the old one. The Ecobond™ binder is unique to us and is specially formulated to our exacting specification so that it works perfectly with our rubber shred coating, the on-site mixing process and our proven installation techniques so we will regularly use an 18% ratio with some flexibility for on-site variations on the day.

Note that for Gummibond™, your order is not for a quantity of material, but is accepted for a given square meterage and the given site conditions and will include generous ‘overs’ in the amount of material we provide to site to cope with on the day variables.

Groundworks & preparation

Geotextile: Whilst a geotextile or weed control fabric is normally used to control weed growth; in the case of the Ecobond™ system the rubber mulch leaves no space for light to penetrate so weed growth through the surface is never an issue. However, we still would normally use a geotextile as a physical barrier so that stones and other debris do not get into the mix whilst it is being spread. So that it does not tear underfoot or from the spreading a tear-resistant high-grade material should be used.

Drainage: If there is not a problem with drainage and sitting water at the moment, then installing our mulch will not create one as it is totally permeable. However, it will not solve an existing drainage issue either (although as our mulch will effectively raise the surface level by 40mm it may help?).

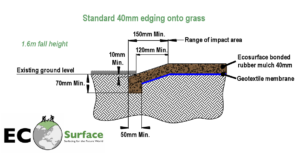

Grass: Long grass should be mowed short, but not killed off altogether. We do not recommend the removal of the top layer of turf as it is more secure to lay the mulch on top of a stable surface and not a disturbed surface of loose soil. Consideration should be given to how level the finished surface should be as the Ecobond™ rubber mulch system can flex and move to follow the existing undulations or you can allow extra material to fill in the voids.

Recently dug or recently replaced soil, wooden bark & sand: It is not a problem installing the Ecobond™ system directly over most loose ground as in these situations it will move and flex to absorb any post-install ground movement and it will even bridge gaps beneath. But the issue with laying on any ground that may latterly move or get washed away is that it may result in unwanted post-install undulations and or soft spots in the surface. If this is not acceptable for the site in hand, then the existing ground should be compacted or aggregated to avoid any future movement.

Concrete Crushed stone / MOT: No problems

Old rubber tiles: Leave in place and recover*

Grass mats: Leave in place and recover*

Wet pour: Leave in place and recover*

*note that this saves considerable cost of removing and disposal of the old surfacing but there are some ‘ifs and buts’ to talk to us about if you are considering this.

Use of Primer: When edging into hard surfaces such as concrete, or edging up to existing solid walls, or finishing the edge into a channel; then to improve the adhesion we recommend precoating the existing surface with our primer.

Edging techniques: To avoid possible finger traps and premature damage, edges should always be dug into a channel and finished into the surrounding surface. We do not charge for chase cutting the edging into grass and other soft surfaces, however a small extra charge may be applied if we need to cut into concrete, old mats, or other surfaces that take longer and needs increased costs for the cutting tools.

Depth

In all situations we expect to lay our Ecobond™ mulch system on top of the existing ground or the Pro Base Pad™ to a depth of 40mm.

This is significantly less than most others who may suggest 80mm – 120mm to get the same performance. Note that if you use more than 40mm above ground you are likely to interfere with the ground clearance of any play equipment; and if digging down to fit it in, will result in extra cost for groundworks, waste disposal etc.

Conversely, in order to appear cheaper, some may suggest using as little as 20mm of rubber mulch, but we know that this does not work. Suggestions of using an additional base layer of cheaper rubber pieces beneath a 20mm mulch layer will also not work.

Fall height protection

As we did not want to employ a lawyer to write this section for us we will keep it simple and generic.

In principle, a spherical weight containing sensors (representative of a head) is dropped from a frame and by measuring the bounce and rate of deceleration, the resulting number indicates how likely a person is to die from the impact. In no way can it show that it is safe to fall from any height, as most ‘heads’ will not fall directly vertical and will have bodies attached to them!

Approved test houses are accredited to certify that the testing procedure has been carried out onto a concrete floor in accordance with BSEN1177 procedures on that given day. Note that it is not possible to fail a test, as any surface will gain a result. Regardless of what some companies may tell you, there is no such thing as a certificate of performance that will tell you how a surface will perform in actual use or in the future.

The fall heights that we publicise have all been tested by an approved test house and in accordance with BSEN1177 standards. However, we also have a lot of data that we do not publish but are happy to discuss if requested.

At Ecosurface we possess our own test rig, calibrated & identical in every way to those used by the certified test houses and this means we carry out 100’s of tests to understand how our surfaces may work in a huge variety of situations, including seasonal weather, different ground conditions, various base layers etc. These give us the same detailed performance reports but as we are not an accredited test house we are not authorised to issue certificates but in our opinion are more likely to represent real-life use.

Our test rig and operator can be made available to hire on a day rate. Please call us if this is of interest to you.

Training packages

Please call us to discuss any of our training packages, installation support and site management services.